PQL ferromagnetic index meter

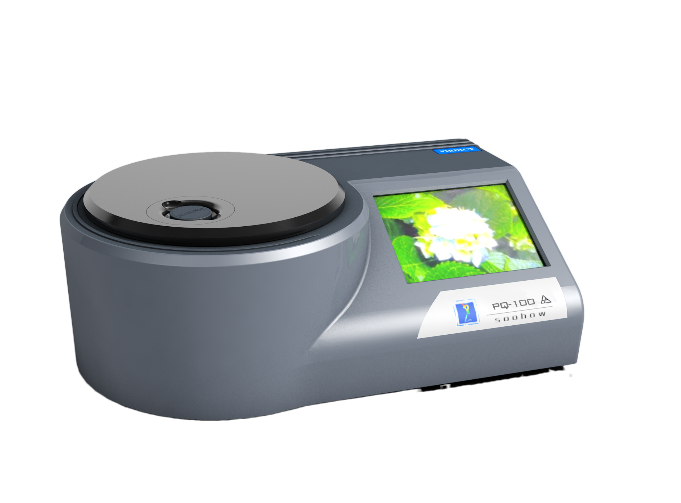

PQL -Ferrous Debris Monitor PQ100

Instrument Introduction:

In terms of detection methods, the current iron content detection mainly includes atomic absorption method and atomic emission method. Although atomic absorption spectroscopy is accurate, its speed is slow and its operation is complex. Atomic emission spectroscopy has been widely used, but it cannot effectively detect large wear particles (whether it is a rotary electrode or inductive ion coupling). Not sensitive to large particles, sometimes fatal in monitoring and diagnosis, as particles normally worn by friction pairs are generally less than 10 μ m. And>15 μ The metal particles of m are generated due to abnormal wear.

As for the detection of iron particles, the compensatory method is to increase iron content monitoring and use an iron content meter. The iron meter developed by our company is a measuring device based on the principle of electromagnetic induction. A sensitive electromagnetic coil is built into the measuring device. When the oil is put into the magnetic field, the ferromagnetic abrasive particles in the oil will cause changes in the magnetic field strength. The size of the coil electromagnetic induction strength has a good correlation with the content of ferromagnetic abrasive particles. It can conveniently and quickly detect the content of ferromagnetic metal particles in lubricating oil, hydraulic oil, and lubricating grease, thereby judging the mechanical wear condition.

Performance characteristics:

1. Adopting patented sensors and signal processing circuits, with good stability and high sensitivity.2. The oil sample transmission and measurement are automatic, and one data can be measured in 10 seconds.

3. Equipped with PC data management software, measurement data can be directly imported into the computer for data management, trend analysis, curve printing, etc.

4. The oil sample does not need to be processed and can be directly injected into an oil bottle for measurement.

5. Chinese and graphical interface, convenient for user operation and use.

6. You can input any number and letter, and users can name the file.

Technical parameter:

1. Power supply: AC220V ± 10%, 50-60Hz;2. Environmental temperature: 0 ℃~30 ℃;

3. Display screen: LCD120 × ninety;

4. Repeatability: ± 4PQ or ± 1% [whichever is greater];

5. Resolution: 1PQ;

6. Test time: 7 seconds;

7. Measurable minimum value: 5PQ;

8. Detection range of abrasive particles: > 1 μ M ferromagnetic abrasive particles;

9. Serial port connection method: USB mother port;

10. Measurement range: 0-15000PQ;

11. Size: 371mm * 226mm * 138mm (length * width * height);

12. Weight: 3.8kg.

Navigation column

News Center

Contact Us

Address: Room 1001, 1st Floor, Building B, No. 555 Dongchuan Road, Minhang District, ShanghaiTel: +86 13776312896

Mobile: 13776312896

Contact person: Manager Xu

Email: xrw@soohow.com

Website: www.soohow.com